Low-pressure polyethylene sheet is produced by flat-slot extrusion from thermoplastic ethylene polymer obtained at low pressure.

Low pressure polyethylene (high density) is a very hard and durable material. Polyethylene sheet is indispensable in many areas of application due to the successful and rare combination of mechanical strength, chemical and radioactive resistance, excellent dielectric properties, frost resistance, moisture resistance, as well as lightness and harmlessness, low pressure.

Low-pressure polyethylene sheet is welded by all main methods: hot gas, filler rod, friction, resistance welding.

Polyethylene sheets are difficult to bond and require complex surface treatments.

Brittle in direct sunlight if not properly stabilized.

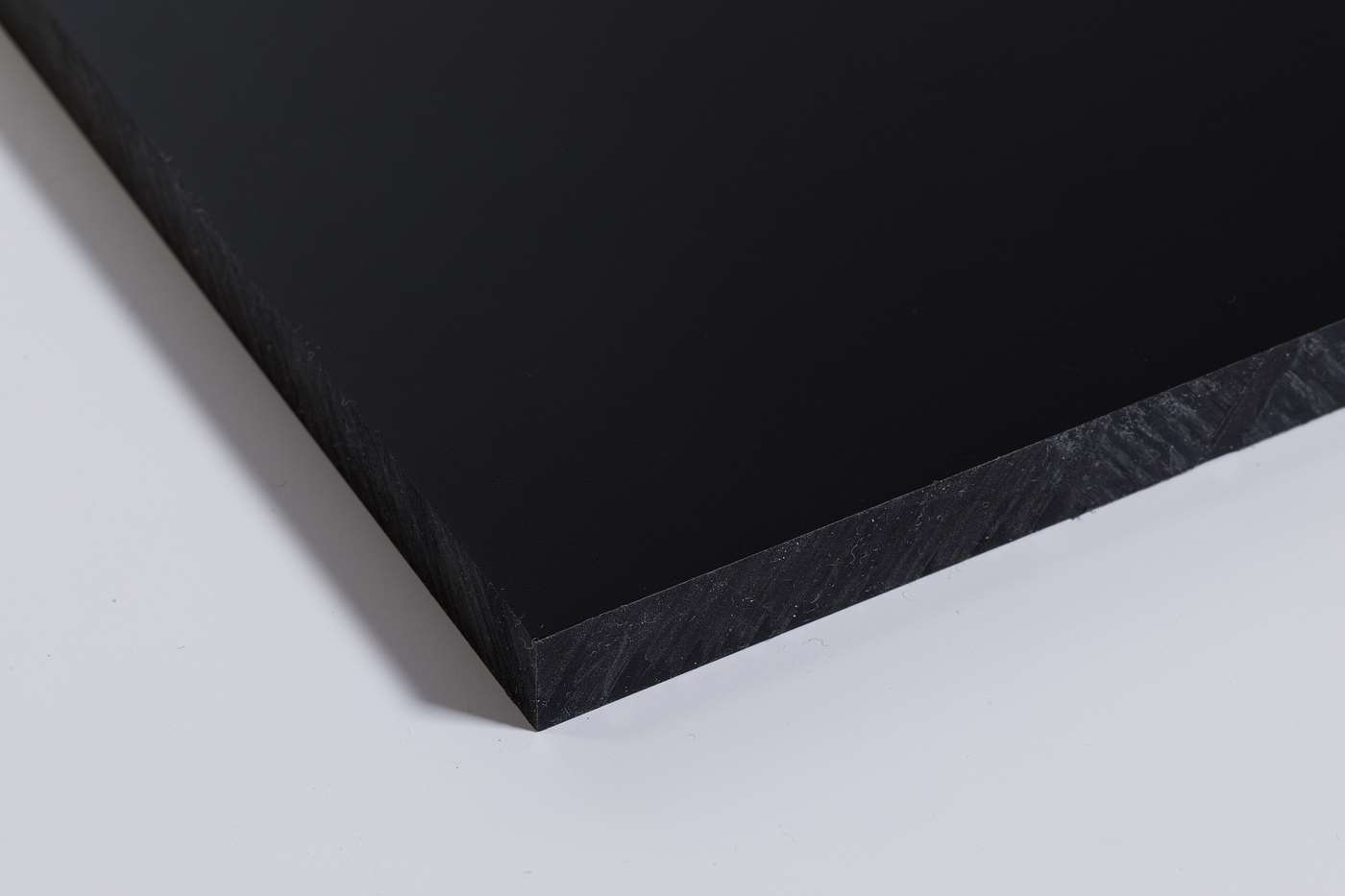

or electrical engineering, sheets are produced from special grades with a specific volume resistance of 103-108 Ohm*m in black.

It is possible to laminate the sheet with non-woven material to insulate pipelines and the possibility of gluing to metal when lining containers.

Application area

- Automotive industry:

- wheel arch liners

- car gas tanks

- locker

- containers for transportation and storage

- meat and fish products (boxes, boxes)

- containers for chemical reagents

- boards for cutting meat, fish, etc.

- pool bowls and decorative ponds

- fish breeding tanks

- septic tanks and grease traps

- geogrids and geomembranes

- sleds and snowmobile bottoms

- playgrounds

Processing methods

- Mechanical processing (cutting, sawing, drilling)

- Laser cutting, etc.

- Forming

- Contact welding, ultrasonic, gun, extruder

- Bending

Delivery form

- Thickness from 0.6-30 mm

- Width up to 2100mm

- Smooth or embossed (“leather”)

- The surface is protected with PE foil on one or both sides

Chemical properties

Resistant:

- To acids

- To alkalis

- To gasoline

- To oils

- To alcohols

- To salt solutions

- To water

- To almost all organic solvents at temperatures up to 60 °C

Not resistant:

- to strong oxidizing agents

- to ozone

- to chloroform

- to aqueous chlorine solution

- to nitric acid with a concentration of more than 50%

Operating temperature

- Material with long lasting

- Heat resistance up to 80 °С

- Allows cooling down to -50 °С

Flammability indicators

- Burns up under the influence of a flame or when an appropriate heat amount is supplied

- On contact with an open flame burns with a smoky flame with the formation of droplets

- Self-ignition at a temperature of 417 °C

- Ignition temperature 306 °С

Characteristics of HDPE sheet

| Units | Testing Method, ISO | Value | ||

|---|---|---|---|---|

| Density not less | g/sm3 | 1183 | 0.96 | |

| Tensile yield strength | MPa | 527-2/1В/20 | 24 | |

| Elongation at break | % | 527 | 700 | |

| Charpy impact strength on sample without notch (rib) | -40°С | kJ/m2 | 179/1fU | н/р |

| Charpy impact strength on sample without notch (rib) | -50°С | kJ/m2 | 179/1fU | н/р |

| Charpy impact strength on notched specimen (rib) | 23°С | kJ/m2 | 179/1ерА | 25 |

| Charpy impact strength on notched specimen (rib) | -30°С | kJ/m2 | 179/1ерА | 15 |

| Charpy impact strength on notched specimen (flat) | -40°С | kJ/m2 | 179/1ерА | 10 |

| Charpy impact strength on notched specimen (flat) | -50°С | kJ/m2 | 179/1ерА | 10 |

| Flexural modulus | MPa | 178 | 1000 | |

| Bending temperature under load | 1,80 MPa | °С | 75-2Aе | 48 |

| 0,45 MPa | °С | 75-2Ве | 75 | |

| Vicat softening point | 50Н/120°С | °С | 306/В120 | 78 |

| Shore hardness | Method D | 868 | 67 |

* The above values refer to the state of the thermoplastics immediately after extrusion and do not take into account the effects of aging.

* The properties of the sheet may vary depending on the properties of the raw materials used

«Typical malfunctions during thermoforming and their elimination methods» you can download here

CALL US

8 (800) 770-05-52 (free within the Russian Federation)

Togliatti

+7 (8482) 69-10-20

+7 (8482) 69-10-30

+7 (8482) 69-10-31

Moscow

+7 (926) 838-75-93

+7 (915) 176-38-87

Rostov-on-Don

LEAVE AN APPLICATION ONLINE

You can also order plastic sheets

by filling out the detailed online order form on our website.

Additional Information

Low-pressure polyethylene sheet is a leader among all produced synthetic polymers, copolymers and composite materials in popularity and application possibilities. Low price of feedstock, recyclability and good manufacturability have determined HDPE as one of the most cost-effective materials for almost universal use. Low-pressure polyethylene sheets are easy to vacuum-pneumatic and mechanical thermoforming, they are well cut, drilled, glued and, moreover, have a high impact strength at low temperatures which expands the range of HDPE applications.

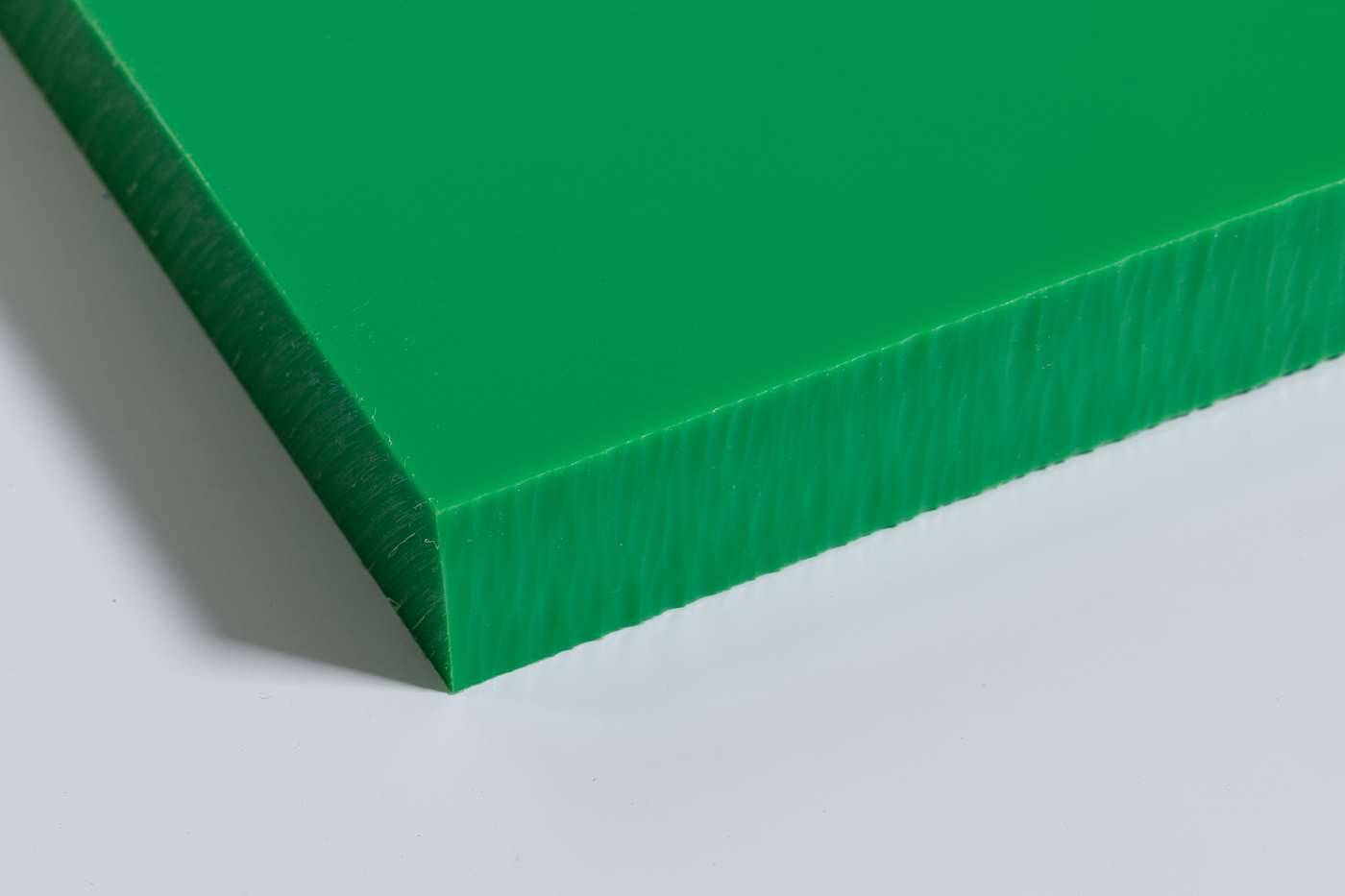

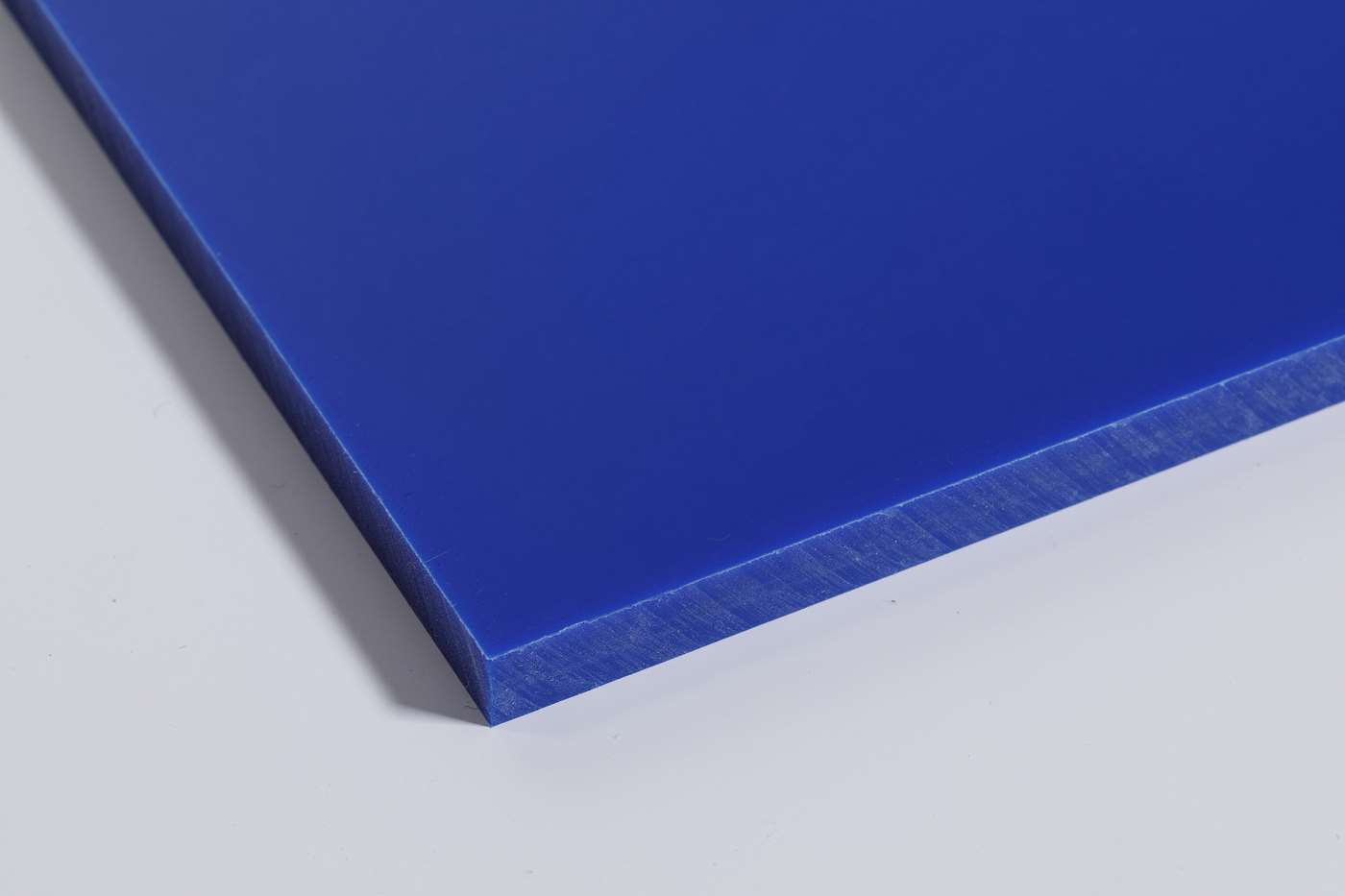

Polyethylene sheets are highly resistant to cracking, including good impact resistance at subzero temperatures. It can be produced in various colors depending on the customer’s requirements. UV stabilization is possible.

HDPE sheets are perfectly formed and easy for machining, as well as welding with hot gas, filler rod, friction, resistance welding.

The HDPE (low pressure polyethylene) sheet produced by flat-slot extrusion, the raw material for which is a thermoplastic ethylene polymer, has a successful and rare combination of mechanical strength, chemical and radioactive resistance, and moisture resistance. This makes high-density polyethylene sheets indispensable for many applications.

Low-pressure polyethylene sheet (HDPE) from the LADA-LIST company can be produced in any color at customer’s request. The outer surface of the sheet can be either smooth or embossed. The equipment used by OMIPA, KUHNE, BANDERA, KAUFMAN, VIRGINIO MAI allows you to accurately achieve the requirements of the technological process, ensuring that the material meets the strictest standards.

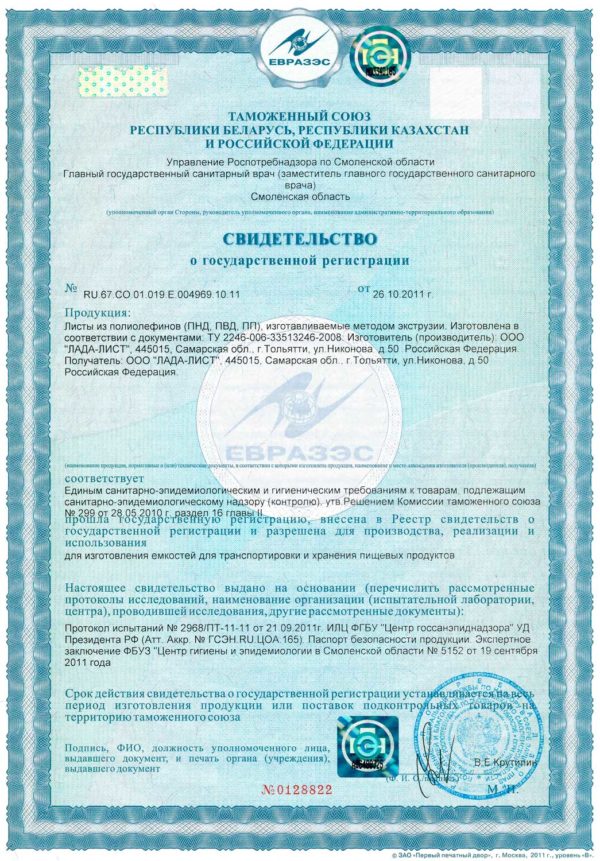

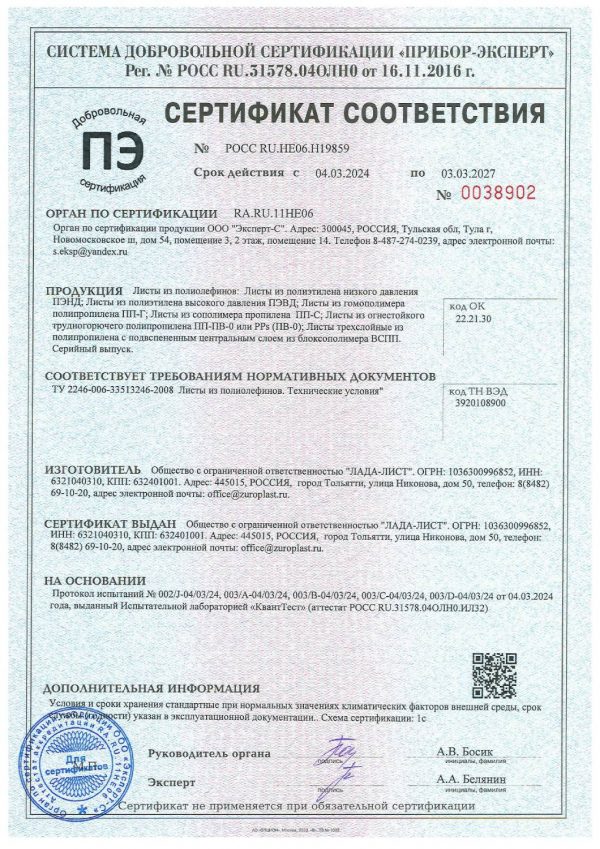

Cooperation with us is an opportunity to purchase high quality HDPE wholesale from the manufacturer at the most favorable prices. The LADA-LIST company sells throughout Russia, satisfying the needs of customers from various industries, including MAZ, GAZ, LiAZ, BOSCH and others. Our products are certified by the international body “TÜV TURINGEN” and the Federal Agency for Technical Regulation and Metrology for compliance with ISO and GOST.