ABS (acrylonitrile-butadiene-styrene) plastic sheets produced by multilayer flat-slot extrusion and is of great demand among polymers for the manufacturing of products by the method of thermo-vacuum forming. High mechanical strength and impact resistance, resistance to high and low temperatures make plastic sheets indispensable in many industries. The operating temperature ranges from -40 to +80 degrees, and enable to withstand short-term heating up to 100 ° C. The products are highly resistant to deformation and impacts, dimensionally stable and lighter in comparison with fiberglass parts. ABS plastic has good chemical resistance. Plastic is dyed well, so any shades are available. Imparting weather resistance, upon request, light stabilizers are introduced into the polymer to prevent aging of products under the influence of solar radiation while being used outdoors. It is possible to manufacture sheets of ABS plastic with an anti-reflective (matt) surface at customer’s request.

Application area

- Exterior parts for cars, buses, tractors, agricultural machines, etc. (panels, casings, roofs, fenders, bumpers, spoilers, side skirts, etc.)

- Suitcase cases

- Internal parts of refrigerators

- Plumbing equipment

- Finishing facilities

- Outdoor advertising products, etc.

- Cases for medical devices and equipment

Processing methods

- Pneumatic vacuum forming

- Machining

- Printing, varnish

- Hot knurling

- Welding

- Gluing

Delivery form

- Thickness: 1-10mm

- Width: up to 2200 mm

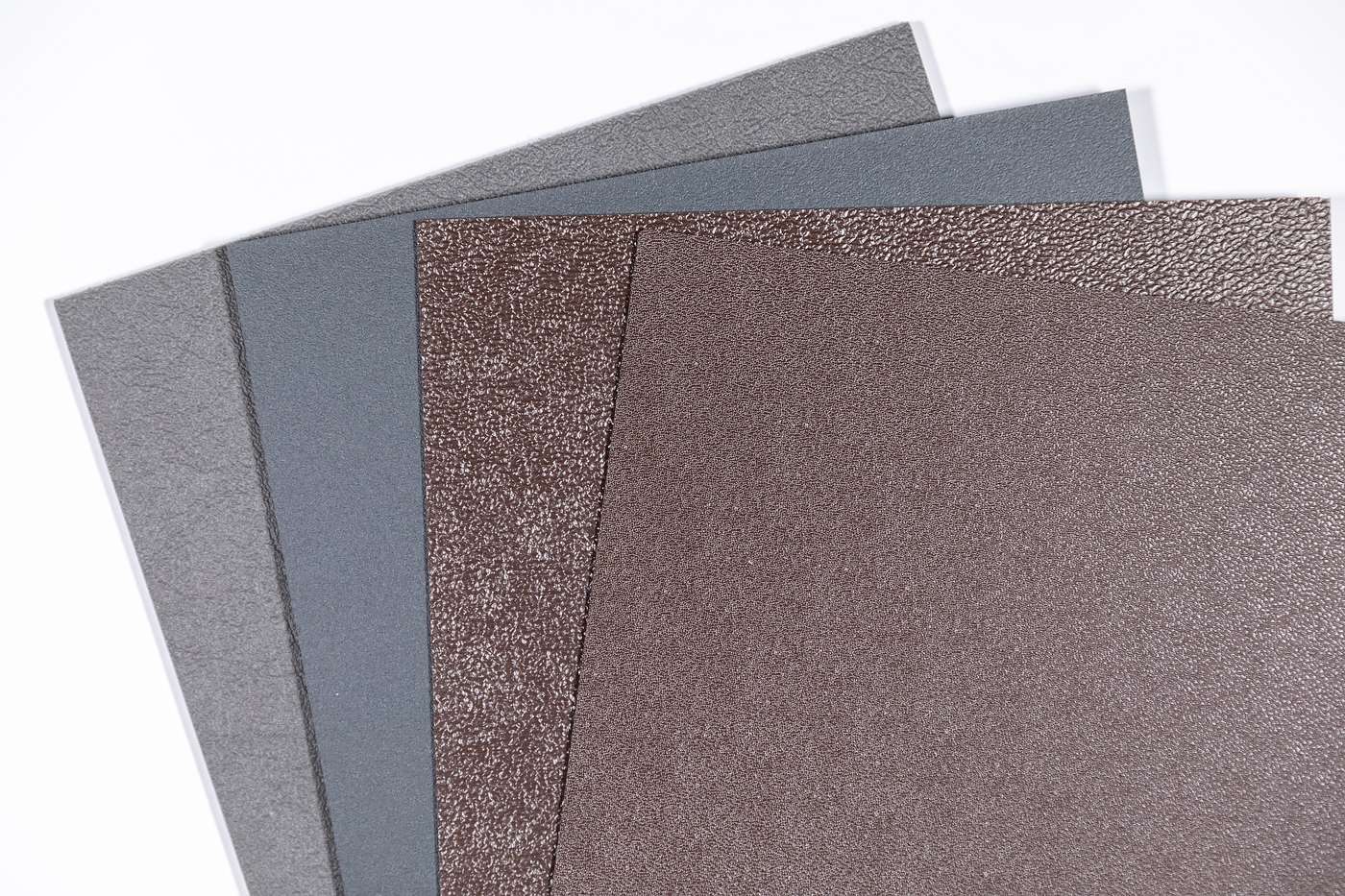

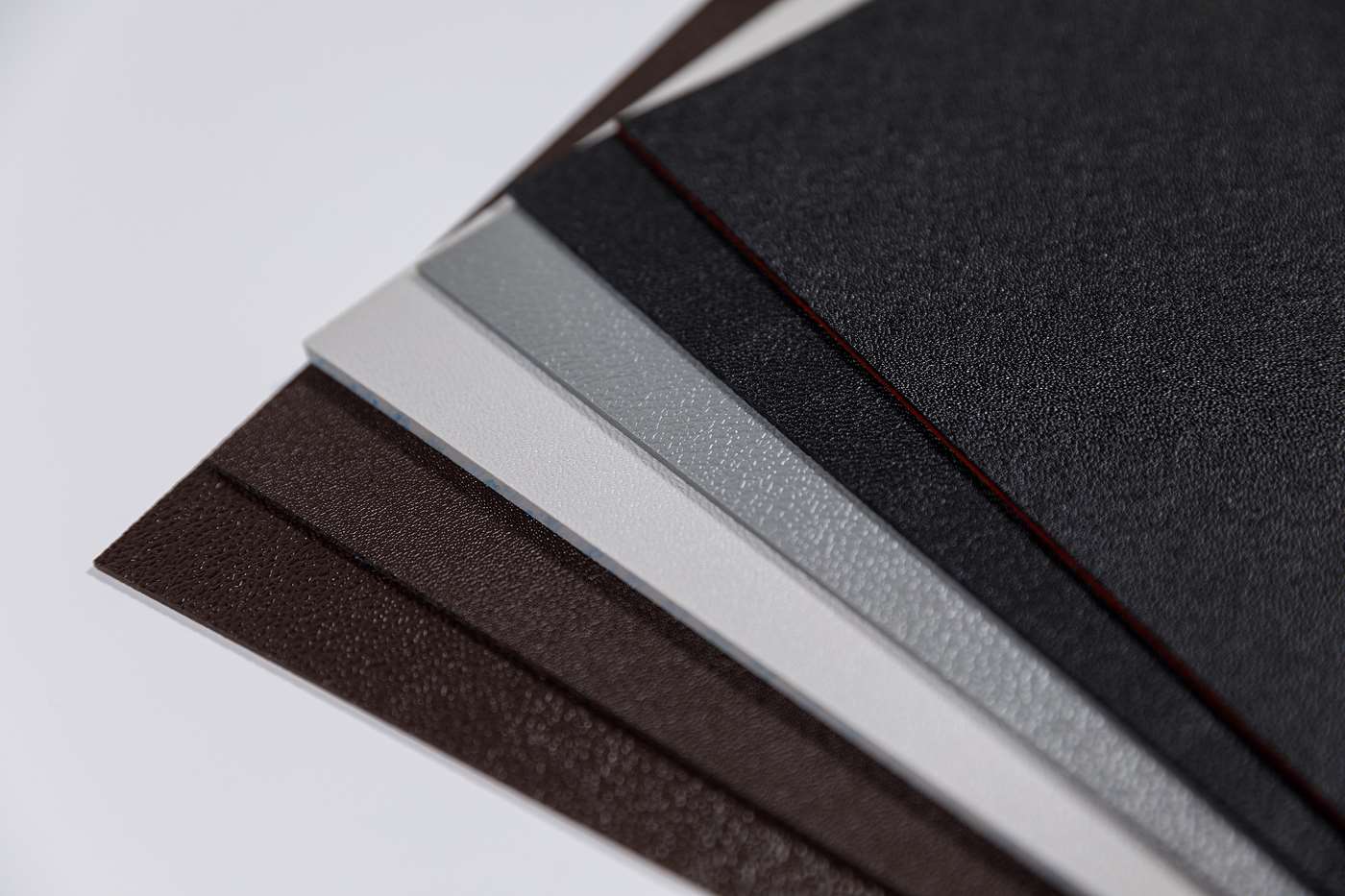

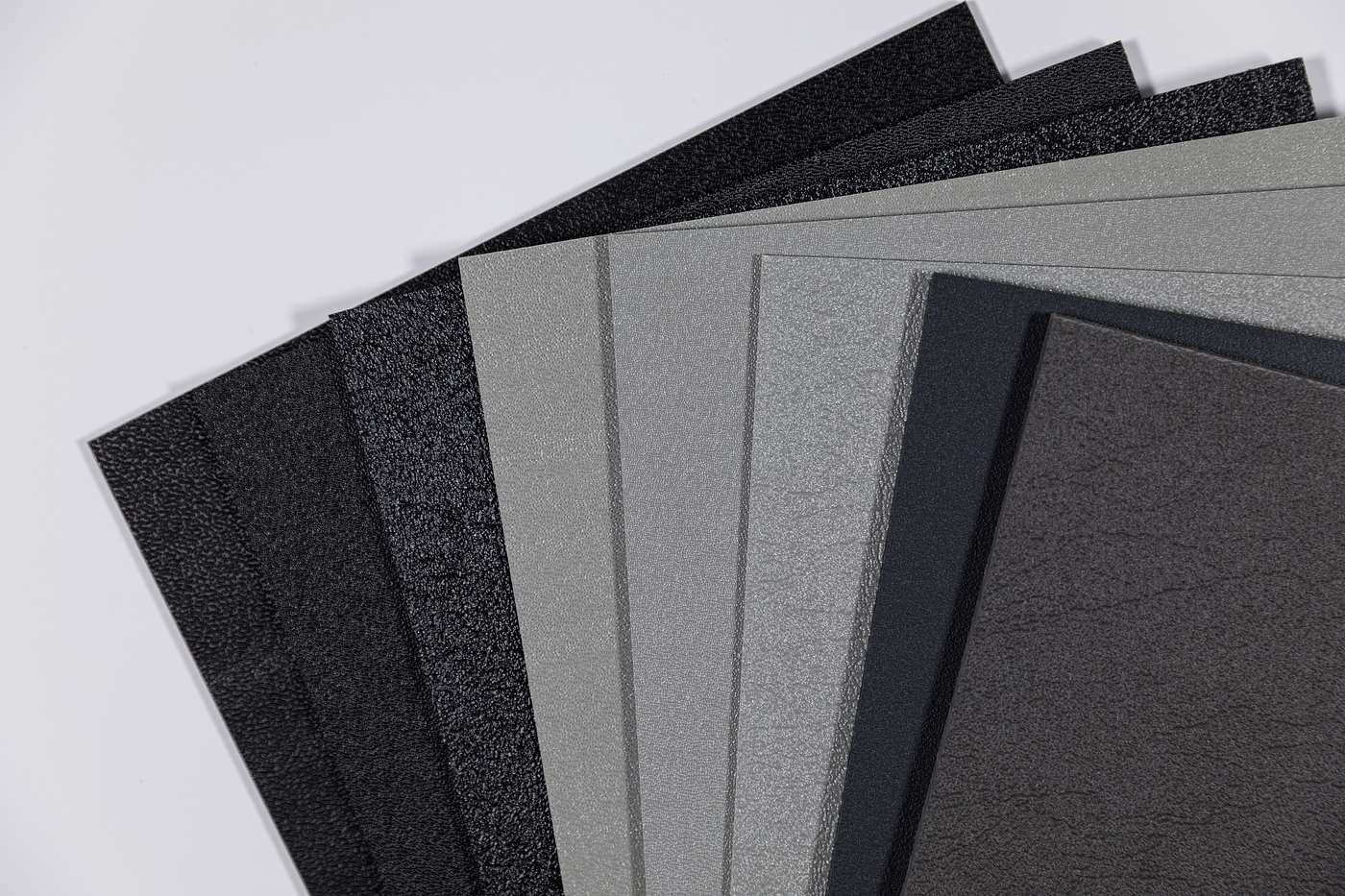

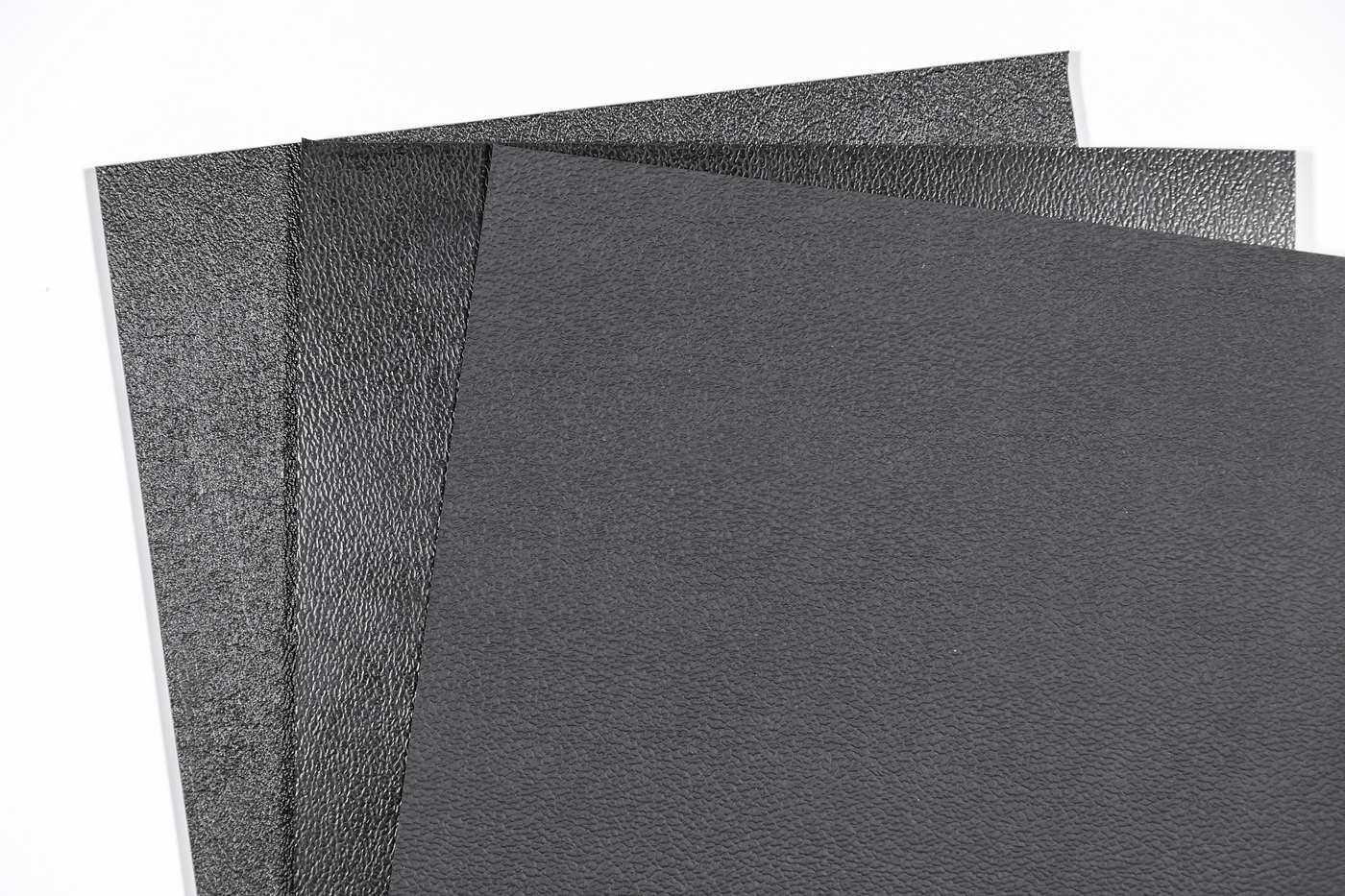

- Smooth or embossed relief (“leather”, “sand”)

- Glossy, matte or extra matte surface

Chemical properties

Resistant:

- To water and aqueous solutions of salts

- To dilute acids and alkalis

- To saturated hydrocarbons

- To vegetable and animal oils and fats

Not resistant:

- To aromatic hydrocarbons

- To chlorinated hydrocarbons

- To concentrated inorganic acids

- To strong oxidants

Operating temperature

- Maximum temperature of long-term operation: 75-80 ° С

- ABS can withstand short-term heating up to 90-100 ° С

- Heat resistance up to 110-130 ° С

It is possible to produce sheets of heat-resistant ABS according to the customer’s request.

Flammability indicators

- Burns up under the influence of a flame or due an appropriate amount of heat burns brightly and unstably after being removed from the flame with a strong formation of soot

- Spontaneous combustion at 350 °С

- Ignition from an external source at 450 °С

Characteristics of ABS (Acrylonitrile Butadiene Styrene)

| Units | Testing Method, ISO | Value | ||

|---|---|---|---|---|

| Density not less | g/cm3 | 1183 | 1.05 | |

| Tensile yield strength | MPa | 527-2/1B/20 | 33 | |

| Tensile yield strength | % | 527 | 25 | |

| Charpy impact strength on sample without notch (rib) | 23°С | kJ/m2 | 179/1ерА | n/a |

| Charpy impact strength on sample without notch (rib) | -30°С | kJ/m2 | 179/1ерА | 25 |

| Charpy impact strength on notched specimen (ribbed) | 23°С | kJ/m2 | 179/1ер | 25 |

| Charpy impact strength on notched specimen (ribbed) | -30°С | kJ/m2 | 179/1ер | 13 |

| Bending temperature under load, not less | 1,8 MPa | °С | 75-2Ае | 87 |

| Vicat softening point | 50Н/50°С | °С | 306/В50 | 95 |

* The above values refer to the thermoplastics immediately after extrusion and do not take into account the effects of aging.

CALL US

8 (800) 770-05-52 (free within the Russian Federation)

Togliatti

+7 (8482) 69-10-20

+7 (8482) 69-10-30

+7 (8482) 69-10-31

Moscow

+7 (926) 838-75-93

+7 (915) 176-38-87

Rostov-on-Don

LEAVE AN APPLICATION ONLINE

You can also order plastic sheets

by filling out the detailed online order form on our website.

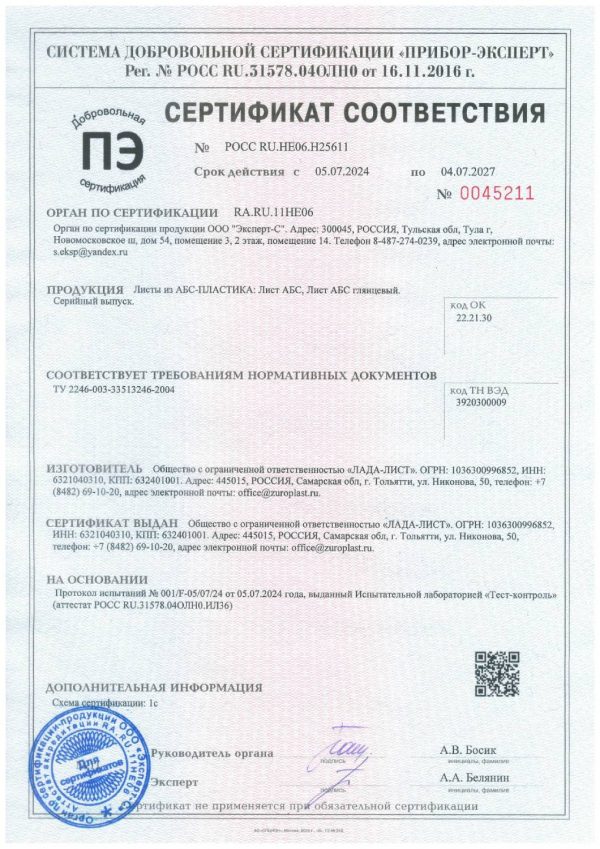

The LADA-LIST company produces and sells high-quality sheet ABS (acrylonitrile butadiene styrene) in Samara region and throughout Russia.

We use the flat-slit extrusion method and can develop a sheet formulation according to the client’s specifications, combining the properties of five layers of different ABS grades in one sheet.

Sheet ABS plastic and its compositions are used in the following areas:

- Automotive industryCar tuning, sills, door trims, window frames, dashboards, frames, bumpers, panels and other details.

- Household appliances manufacturingrefrigerators, microwave ovens, water heaters

- Advertising equipment productionstands, banners

- Construction industrymaterials for interior and exterior decoration of houses

- Production of consumer goodscases for suitcases, boxes, household accessories

Why is it worth buying ABS from LADA-LIST?

Our company produces ABS sheets with a thickness of 0.9 to 10 mm and an embossed and smooth surface, resistant to mechanical damage and weathering, the surface is glossy, matte or extra matte.

ABS “ZUROPLAST” has the following advantages:

- Wear resistant

- Shockproof

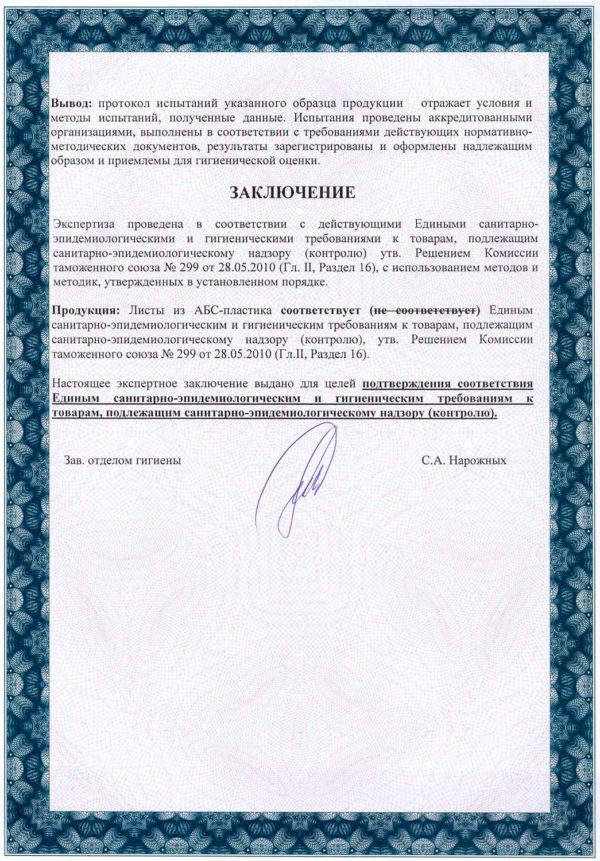

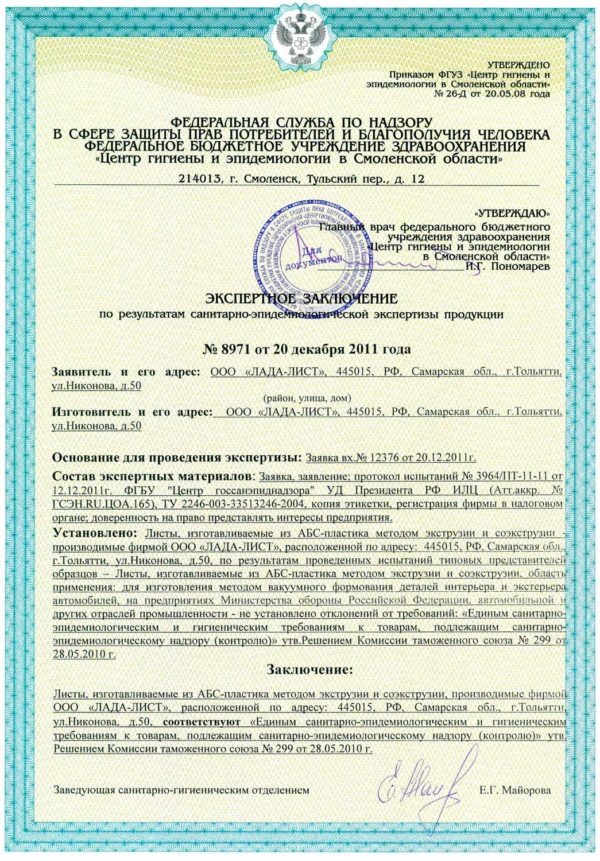

- Non toxic

- Able to withstand temperature extremes -50 °С - + 80 °С

- Electrically conductive or anti-static

- Resistant to solutions of inorganic salts and acids, to alkalis, lubricating oils, gasoline, hydrocarbons, fats and oils

Note: not resistant to ketones, aldehydes, esters, acetone, ethers, benzene, toluene, trichloroethylene and xylene.