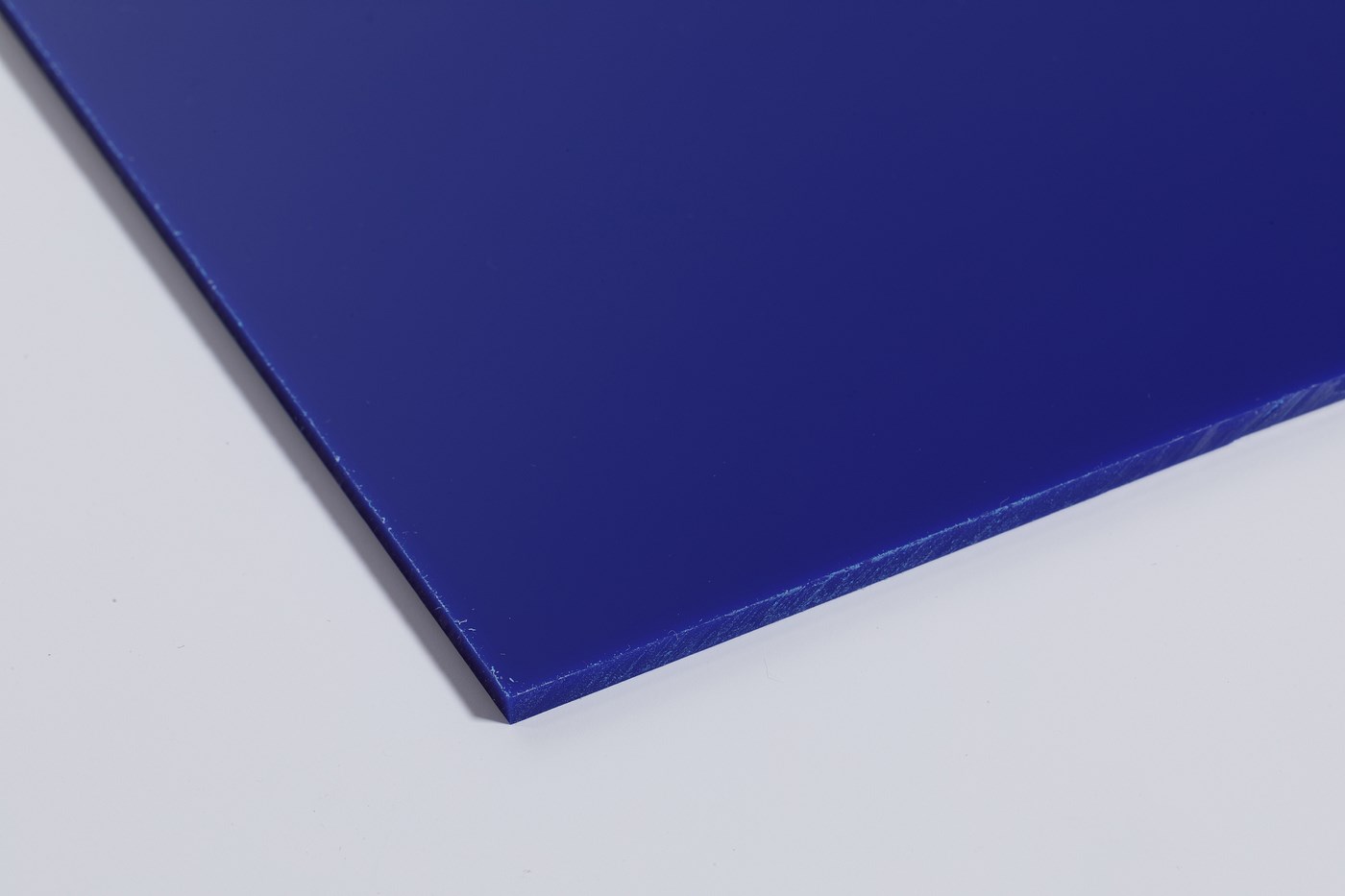

ABS-PC plastic sheet – is a sheet of composite material based on polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS) with an excellent combination of mechanical, thermal and rheological characteristics. ABS / PC parts have good surface quality, rigidity, cracking high resistance, thermal stability, high impact resistance even at low temperatures. The fire resistance of ABS / PC sheets and products is much higher than of ABS plastic sheets.

he composition is a good dielectric.

Electrical strength = 20-30 kV / mm bulk electrical resistance = 1016 Ohm*cm

Application area

- Interior trim parts

- Exterior parts for buses and cars

- Manufacture of electrical and electronic devices

- Office equipment enclosures

- Electrical and electronic products

- Appliances

- Suitcases

- Sports goods

Processing methods

- Pneumatic vacuum forming

- Machining

- Printing, varnish

- Hot knurling

- Welding (ultrasonic, hot plate, friction)

- Gluing

Delivery form

- Thickness: 1-10mm

- Width: up to 2200 mm

- Smooth or embossed (“leather”, “sand”)

- Surface

- Glossy

Chemical properties

Resistant:

- To alcohols

- To salt solutions

- To oils

Not resistant:

- To alkalis

- To aliphatic hydrocarbons

- To chlorinated hydrocarbons

Operating temperature

- Maximum temperature of long-term operation 100-110 °С

- Short-term heating without loading up to 130-145 °С

- Minimum operating temperature – 40 °С

Heat resistance depends on the polycarbonate percentage

Flammability indicators

- Burns up under the flame influence or due to an appropriate heat amount

- Burns brightly and unstably after being removed from the flame by a yellow flame with strong formation of soot

- Self-ignition at 486 °C

- Combustion from an external source at 343 °C

Characteristics of ABS/PC sheet

| Units | Testing Method, ISO | Value | ||

|---|---|---|---|---|

| Density not less | g/sm3 | 1183 | 1.11 | |

| Tensile yield strength | MPa | 527 | 35 | |

| Elongation at break | % | 527 | 10 | |

| Charpy impact strength on sample without notch (rib) | 23°С | kJ/m2 | 179 | н/р |

| Charpy impact strength on sample without notch (rib) | -30°С | kJ/m2 | 179 | н/р |

| Charpy impact strength on a notched specimen not less than | 23°С | kJ/m2 | 179/1ерА | 40 |

| Flexural modulus not less | MPa | 178 | 2200-2300 | |

| Bending temperature under load, not less than | 1,8 MPa | °С | 75-2Ае | 105 |

| Vicat softening point not less than | 10Н/50°С | °С | 306/А50 | 135 |

| 50Н/50°С | °С | 306/В50 | 120 |

* * The above values refer to the state of the thermoplastics immediately after extrusion and do not take into account the effects of aging.

* The properties of the sheet may vary depending on the properties of the raw materials used

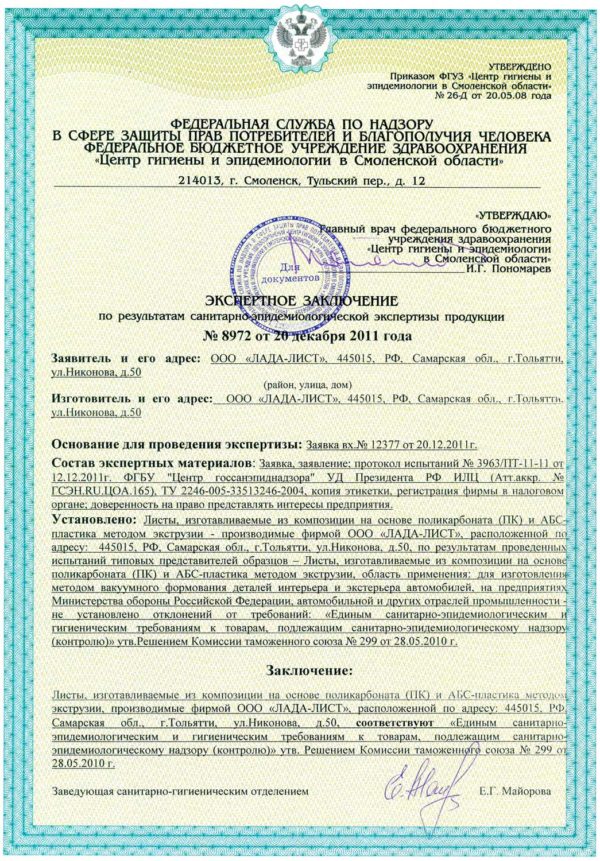

Certificates

«Typical malfunctions during thermoforming and methods of their elimination» you can download here

CALL US

8 (800) 770-05-52 (free within the Russian Federation)

Togliatti

+7 (8482) 69-10-20

+7 (8482) 69-10-30

+7 (8482) 69-10-31

Moscow

+7 (926) 838-75-93

+7 (915) 176-38-87

Rostov-on-Don

LEAVE AN APPLICATION ONLINE

You can also order plastic sheets

by filling out the detailed online order form on our website.

Additional Information

Sheets made on the basis of ABS plastic and polycarbonate composition have a higher impact resistance than sheets of ABS plastic. The impact resistance values can be changed by changing the polycarbonate proportion in the sheet. With an increase in the proportion of polycarbonate, the heat resistance of the material also increases. This composition has good resistance to solutions, alcohols, oils.

ABS/PC plastic sheet is a composite sheet based on polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) with an excellent combination of mechanical, thermal and rheological characteristics. ABS / PC parts have good surface quality, rigidity, high resistance to cracking, thermal stability, high impact strength even at low temperatures.

Basically, this material is used in the automotive industry for manufacturing products for cars exterior and interior decoration. Also, household items, sports goods, cases for various appliances and household appliances are made from this composition.

Interior trim parts and exterior view details of buses and cars, production of electrical and electronic devices, office equipment housings, electrical and electronic products, household appliances, sports goods.