PET-G sheet is produced by flat-slot extrusion from a transparent material based on thermoplastic polyester (polyethylene terephthalate) modified with glycol. The modification provides this polymer with a number of advantages over other transparent polymers and incomparable ease of processing.

Glycol has a lower melting point and allows PET-G products to remain transparent under any influences, including those obtained by thermoforming products of complex geometric shapes with low energy consumption. PET-G sheets can be molded even at low temperatures from 100 to 160 ° C. No additional drying is required before thermoforming. With hot bending, the sheets simply need to be heated locally to 100 ° C.

The surface of sheets is protected by thermoformed polyethylene film on both sides, and also activated by a corona discharge for high-quality printing.

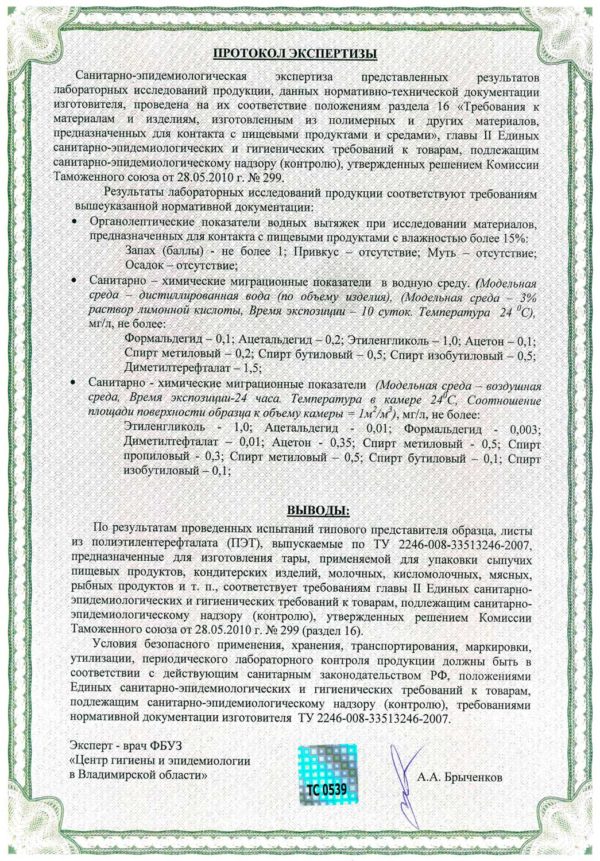

PET-G is non-toxic and can be used in contact with food.

Density of sheet PET-G is 1.27 g/cm³. olumetric electrical resistance of PET-G sheet – 1*1014 Ohm*cm

PET-G sheet is produced only under the order!

Application area

- Screens and displays

- Retail store equipment

- Protective screens

- Price tags

- Refrigeration equipment

- Promotional items

Processing methods

- Processing methods

- Pneumatic vacuum forming

- Machining

- Printing

- Bending

- Bonding with two-component adhesives (polychloroprene or vinyl acetate-based hot melt adhesives)

- Thermal, frictional, ultrasonic, high-frequency welding

Delivery form

- Thickness: 0.75-5.0mm

- Width: up to 2100 mm

- The surface is smooth and glossy

- The surface is protected with PE foil on both sides

Chemical properties

Resistant:

- To water and aqueous solutions of salts

- To dilute acids and alkalis

- To aliphatic hydrocarbons

- To vegetable and animal oils and fats

Not resistant:

- To aromatic hydrocarbons

- To gasoline

- To ketones

Operating temperature

- Maximum temperature of long-term operation: -40 to + 70 °С

Flammability indicators

- It ignites when exposed to a flame or due to an adequate heat amount with a strong odor. Burns with sparks and a little grime

- Does not burn after being removed from the flame (self-extinguishing)

- Spontaneous combustion at temperatures over 400 °C

- Combustion from an external source at 440 °C

PET-G characteristics

| Units | Testing Method, ISO | Value | ||

|---|---|---|---|---|

| Density | g/sm3 | 1183 | 1.27 | |

| Tensile yield strength | MPa | 527 | 50 | |

| Elongation at break | % | 527 | 40 | |

| Notched Charpy Impact Strength | 23°С | kJ/m2 | 179/1ерА | 8 |

| Notched Charpy Impact Strength | -40°С | kJ/m2 | 179/1ерА | 2 |

| Charpy impact strength on sample without notch (rib) | 23°С | kJ/m2 | 179/1ер | н/р |

| Flexural modulus | MPa | 178 | 2100 | |

| Bending temperature under load | 1,80 MPa, | °С | 75-2Ае | 69 |

| 0,45 MPa | °С | 75-2Ве | 72 | |

| Vicat softening point | 10Н/120°С | °С | 306/A120 | 82 |

| 50Н/120°С | °С | 306/B120 | 78 | |

| Shore hardness | Method D | 868 | 117 |

The above values refer to the state of the thermoplastics immediately after extrusion and do not take into account the effects of aging.

CALL US

8 (800) 770-05-52 (free within the Russian Federation)

Togliatti

+7 (8482) 69-10-20

+7 (8482) 69-10-30

+7 (8482) 69-10-31

Moscow

+7 (926) 838-75-93

+7 (915) 176-38-87

Rostov-on-Don

LEAVE AN APPLICATION ONLINE

You can also order plastic sheets

by filling out the detailed online order form on our website.

Additional Information:

PET-G sheet due to the possibility in production at almost complete control over the formation of the crystal structure is significantly ahead of A-PET, PVC, polycarbonate, PMMA sheets in terms of performance properties range, and therefore, at the moment, a transparent PET-G sheet, milk and white opaque PET-G sheet steel is the optimal material for the manufacture of screens, shop windows, displays and protective glazing.

A-PET (amorphous polyethylene terephthalate), PMMA, polycarbonate sheets are inferior to PET-G in terms of print quality, impact strength, and transparent PET-G sheet surpasses most other polymers in translucency, including transparent ABS. Indicative manufacturability of PET-G sheets during vacuum, pneumatic and mechanical thermoforming is also vital. It makes it possible to obtain products of complex geometric shapes and reduce the duration of the technological process.

Sheet plastic made of polyethylene terephthalate glycol is characterized by good impact resistance in a wide temperature range, high transparency, good resistance to fats and mineral acids, the ability to apply high-quality printing, good bending ability, good formability (even for complex configurations, product design accuracy is obtained).

Benefits of PET-G over PPMA

- higher impact strength

- cold bending without bend whitening -increased chemical resistance

- ease of printing on

- improved formability: the possibility of thermoforming at lower temperatures

PET-G advantages over polycarbonate

- increased chemical resistance

- easy cold bending

- ease of printing

- excellent thermoformability:

- does not require pre-drying

- shorter cycle time

- wider processing range

Benefits of PET-G over PVC

- improved optical properties

- more environmentally friendly

- easier to process

Benefits of PET-G over A-PET

- 100% amorphous (not crystalline)

- improved toughness

- more printable

- easier to recycle

PET-G advantages over transparent ABS

- much better transparency

- no whitening at the bend

Material advantages

he widespread use of PET-G sheet is due to a number of unique properties:

- ight transmittance 90% even on sheets with a thickness of more than 2mm;

- high strength under shock and bending loads;

- the ability to maintain properties at low temperatures;

- the possibility of mechanical processing of sheets (cutting, milling, drilling);

- the accuracy of the geometry of parts obtained by thermoforming the material;

- resistance to water, dilute acids, salt solutions, fats and oils.

For the production of sheet PET-G, we use flat-slot extrusion technology. This allows the production of sheets of various thicknesses and dimensions. Both sides can be laminated with a protective polyethylene film. Both surfaces of the sheet are corona treated (activated) and have a high surface tension, which contributes to an even imposition of offset and screen printing. All types of self-adhesive films are perfectly applied to it.

One of the most popular materials from the LADA-LIST company is sheet plastic based on thermoplastic polyester – polyethylene terephthalate (PET-G).

Sheet PET-G, thanks to the use of modern equipment, are of high quality and in full compliance with the required characteristics.